Stenner chemical feed pumps quick and easy to service

Stenner pumps have long been the most popular chemical feeders in Florida. Why? They’re simple and reliable, inexpensive to own and operate, and best of all....quick and easy to service. In the next few issues, we will be examining the tried and true technology that has led to Stenner’s extreme popularity among our technical staff and customers alike. We will be sharing tech secrets and quick tips that will help make you an expert in these rugged feeders.

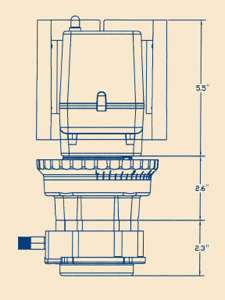

Stenner has been manufacturing peristaltic pumps since 1957. According to Webster, a peristaltic pump is one “in which a fluid is forced along by waves of contraction produced mechanically on a flexible tubing”. Simply put, the feeder uses 3 rollers to squeeze the fluid out the tube much in the same way you squeeze toothpaste out of a tube. The traditional or “classic” Stenner feeder comes in 4 major sizes (50 GPD, 85 GPD, 110 GPD, and 170 GPD).

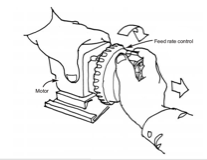

The feeder has three basic parts: the motor assembly (which spins the shaft), the feed rate control (which allows fractional turning of the shaft), and the tube housing (where the 3-headed roller assembly spins over a flexible tube). The clear tube housing allows constant viewing of the feed process, and can help in trouble shooting a feed issue.

The feeder’s simplicity to service is a direct result of the simplicity of design. If a tube wears out, you simply twist and remove the old feed rate assembly and replace with a new one. No tools required (but remember to always wear safety goggles when working with chemical lines). More advanced operators can follow simple instructions to remove and replace a new tube within the tube housing...all with a phillips screwdriver. In the same manner, if the feed rate assembly (which allows the operator to fine tune the fluid output of the pump by turning a dial from 1 to 10) were to require repair or replacement, you simply twist and remove the assembly from the motor, again with no tools required, and replace with a new or rebuilt item. More advanced operators can completely rebuild the feed rate assembly by following simple and concise instructions. Tools required? You guessed it....a phillips screwdriver and, of course, safety goggles.

CES has installed or serviced tens of thousands of Stenner feeders in our 24 year history, and we are very willing to continue that service, or we can assist/train your staff in learning how to work on the various components in-house. We strongly recommend that each organization stock a small amount of inexpensive spare parts, rebuild kits, or spare feeders to help quickly restore a damaged feeder to full working order. We’ll guide you every step of the way.

Stay tuned for more information on the versatile line of quality Stenner feeders.

Tuesday, February 27, 2007

The “classic” Stenner Feeder consists of 3 parts: the motor, the feed rate assembly, and the tube housing. It is self priming, does not need a check valve, and can pump a wide variety of fluids efficiently and reliably.

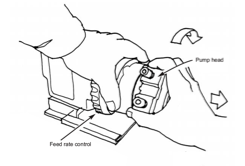

To service or replace the tube housing or feed rate assemblies, simply twist and pull. No tools required

removal of tube housing

removal of feed rate assembly