Tech tips - Maintain Stenner injectors for reliable chemical feed

Stenner chemical feeders will provide years of consistent and reliable dosing, that is if all the chemical passageways are maintained and kept clean and free from calcification. Here are some time-tested ways to easily diagnose issues and maintain this important part of your chemical feed system.

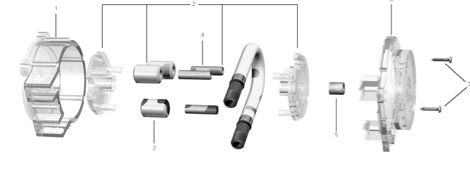

In its simplest form, the Stenner feeder uses a flexible tube and tri-roller assembly to “squeeze” the chemical solutions through the injection tubing (normally 1/4” diameter). This rolling or “peristaltic” motion also draws the solution from the chemical crock, without the use of a check valve.

The tubing installations are easy to understand. A 1/4” line normally run from the chemical storage vat to the suction side of the feeder (tube connection that is closest to the wall). This is the suction side of the chemical pump. It then runs from the output side of the feeder (tube connection that is furthest from the wall) to the injection point. CES tries to run clear tubing in most cases but any clear tubing that is exposed to UV light will quickly degrade and will develop hairline cracks that cause a feed problem. Therefore in outdoor installations, CES will install black tubing.

You can learn a lot from the pumping action of a Stenner feeder if you pay close attention to the tubing and wet-end assembly. Experienced CES technicians will closely observe the behavior of the tube and tubing to give them hint regarding the pumping action of the feeder. For example: if the suction tubing is “bouncing” there is probably a partial clog in the injection point. Under this condition, you will also see a “bloated” tube in between passes from the rollers. To resolve this problem, unclog the injector by disconnecting the line from the injector assembly (MAKE SURE TO ALWAYS WEAR SAFETY GOGGLES), and clear the line using one of the two procedures described above. CAUTION: Chemical feeder lines may be under pressure, and could spray chemicals upon disconnecting from the tube or from the injection point.

You also can verify a clogged injector in the field by a simple dye test procedure. First, unhook the tubing from the suction side chemical feeder connection (closest to the wall), put in 5-10 drops of pH reagent 004 (red dye), and reconnect. Then observe the movement of the dye. If the red dye stays in the suction side of the feeder and does not advance past the feeder housing...you normally have a problem with a clogged injector (see above) OR with the suction side of the feeder including suction tubing, nut and ferrule, or the tube itself. To verify which it is...unhook the pressure side tubing from the feeder (furthest from the wall). If the red dye stays on the suction side, the problem is more than likely the suction line as described above. If the red dye moves through the feeder, then the problem lies in the injection point.

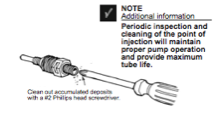

To further troubleshoot the injection point, simply disconnect the tubing from the injector (PLEASE MAKE SURE TO ALWAYS WEAR SAFETY GOGGLES), and remove the tubing while the feeder is still operating . If the red dye pumps through the line then the problem is in the injector itself. Use a #2 phillips screwdriver to unclog and verify proper operation. If the red dye still won’t pump out the loose line, then the tubing itself is clogged. To resolve, simply cut the line at an angle (as shown above), verify proper operation, and reconnect to the injector.

If the dye moves through the feeder and through the injection point, then the feeder is working (moving fluid) properly, and the problem lies in either the feeder solution (acid or chlorine strength), and/or the pool water chemistry.

Your CES representatives stand ready to assist you in getting the most out of your Stenner pumping systems. We can help with additional training, technical support, or with low prices on factory replacement parts and accessories.

Working together, we can help assure that your Stenner feeder is working at peak performance. Only then can we help deliver “Excellence in Water Quality Control”.

Saturday, March 31, 2007

The Stenner wet-end assembly consists of a tube, a tri-roller assembly and a clear housing to allow continual visual observation of the pumping action. This entire assembly is simple to troubleshoot, service, and replace.

If the injector is clogged, simply remove tubing from the injector and unclog using one of several factory techniques.

If the tubing line itself is clogged, simply remove tubing from the injector and trim off 1” (at an angle) to restore fluid flow.

IMPORTANT NOTE:

Make sure to ALWAYS wear

protective goggles when servicing chemical feeders, tubing, or injectors.